Super Retina Resolution

Our scanners have the industry's best resolution of 0.029 mm/pix and an accuracy of 0.010 mm, which makes the scanned object look exactly like the original. We call this Super Retina resolution because the scan result reveals details that are invisible to the naked eye. Our jewelry scanner is the best solution for scanning jewelry, shadow bands, and gemstones.

How Jewelry 3D Scanners Can Benefit You:

Jewelry Creation and Reproduction

- Matching Wedding Bands: Precisely craft identical wedding bands by scanning complex surfaces—ideal for replicating intricate details that are hard to measure manually.

- Heirloom Replication: Create new jewelry pieces based on existing ones without disassembling the originals, preserving sentimental value.

- Gemstone Scanning: Capture the unique shapes and sizes of gemstones to ensure a perfect fit in mountings and bezels.

- Art Preservation: Preserve digital copies of valuable or fragile artworks, reproducing sculptures and decorative elements without risking damage.

Download Scan Examples for Jewelry

Design, Repair, and Prototyping

- Intricate Repairs: Perform complex jewelry repairs by scanning pieces and designing perfect-fitting components.

- Rapid Prototyping: Quickly prototype small parts for industrial design, testing forms and fits before mass production.

- Scaling and Modifying: Scan and scale objects to different sizes, saving significant modeling time.

Miniatures and Collectibles

- Miniature Scanning: Digitally reproduce miniature figurines for collectibles or tabletop games, creating 3D models for printing or virtual reality.

- Coins and Medals: Document and analyze numismatic collections, determining authenticity and assessing item conditions.

Download Scan Examples for Miniatures

Mechanical Components (CAD)

- Watch Parts: Analyze and reproduce small mechanical components of watches, aiding in repair and restoration.

- Mechanical Parts Scanning: Reverse-engineer parts for reproduction or modification, ensuring quality control and precision manufacturing.

- Keys and Locks: Reproduce complex key structures and analyze the security of locking mechanisms.

Scanning process

To scan a model, you need to mount it securely to avoid any movement during scanning.

Models also need to be coated with a special spray that makes them white. Two types of spray are available at present. The first is chalk-based and coats models in small particles of chalk. More modern sprays are specially formulated to dissolve in air over time.

Engineered specifically for high-precision scanning of small gemstones. Unlike other SLS scanners, its camera is oriented horizontally. This allows:

- Scanning gemstones from a single setup, capturing both the top and bottom sides simultaneously.

- Preventing the stones from falling during scanning, unlike other scanners.

Conventional diamond scanners can only scan convex objects. The D3D-s captures every dimple and defect.

The D3D-s includes special stands for scanning gemstones simultaneously from two sides. The scanner tilts the table first to one side and then to the other.

The scanning process yields a 3D model that you can use to create jewelry in a CAD program. You can also showcase your models on your website.

The images above are of a 17-mm gemstone.

3D-scanning miniatures

The D3D-s jewelry 3D scanner is also suitable for scanning miniatures. In fact, it is the best tool for copying a miniature. Only our scanner can provide a faithful reproduction that includes even the smallest details. Other scanners are simply unable to do this or cost ten times more. Look at the scan below. You can see all the defects and even marks from the mold.

High-Quality Equipment

We employ industrial-grade cameras and high-quality lenses, enabling us to deliver superior results. Combined with cutting-edge software based on unique algorithms, you'll receive quality that exceeds the cost of our 3D scanner, the D3D-s. This device is specifically designed to scan objects with retinal resolution, ensuring the finest detail is captured with precision.

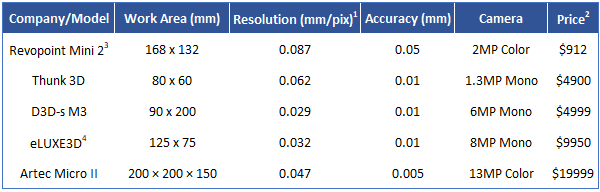

Comparison with Competitors

We are not afraid of competition, so we have combined the features of jewelry scanners currently on the market into a comparative table for your convenience.

All mentioned trademarks belong to their respective owners.

1. The formula used for calculation was - Working area width (mm) / Camera resolution (pix).

2. The price is obtained from open sources and may differ from the current one, please clarify with the seller.

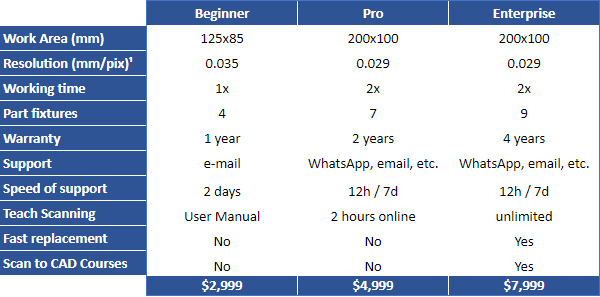

Select Your D3D-s Scanner Model

Discover the perfect 3D scanner package tailored to your needs. Whether you're a beginner exploring 3D scanning or an enterprise seeking advanced capabilities, we offer options to suit every requirement and budget. Compare our packages below to find the one that's right for you.

Minimum System Requirements

- 64-bit Windows 8/10/11

- 16 GB RAM

- NVIDIA card with 2 GB RAM

- Fast SSD (recommended)

- 4GB of HDD free space

- USB 3.x Type-C

Software

We developed software specifically for the D3D-s with lots of unique features. The software is currently available for Windows 8/10/11. Once the scanning is done, you'll get an STL file that you can open in any program that supports STL files, such as ZBRUSH, RhinoGold, MatrixGold, Jewelery cad dream and more.

Unlimited support

For your convenience, we have introduced unlimited online support. Ask us as many questions as necessary until you learn how to use the scanner confidently. We provide online training and quick support via WhatsApp. You will be assisted by one of the engineers who designed the scanner, so the information you get will be highly reliable. One hour is usually enough for us to explain how the scanner works. We are always happy to help you and admire your great results.